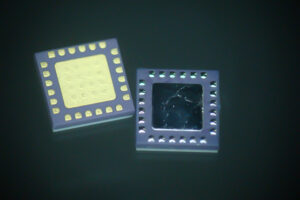

Tintronics used an automated/robotic hot solder dip station to apply a hot solder tinning dip to a QFN chip, which is used in a military radio frequency application for the defense industry. The company used Sn63 Pb37 solder and ORH1 flux and ground the plane co-planarity down to .002”. Inspection/lead scanning as well as visual and final inspections were also completed. The application meets the defense customer’s specifications, as well as ANSI/ESD S20.20 IPC J-STD-001 and IPC/JEDEC J-STD-033 standards on the low-volume production runs.

Specifications about this QFN Chip for the Military

| Product Description | This QFN power amplifier is used within a radio frequency application | |

| Capabilities Applied/Processes | Primary: Tinning | Secondary: Inspection/Lead Scanning |

| Equipment Used to Tin Part | Automated/Robotic Hot Solder Dip Station | |

| Tightest Tolerances | Ground plane coplanarity down to .002 | |

| Material Used | Sn63 Pb37 Solder J-STD-004 | |

| In process testing performed | Visual Inspection Final Inspection | |

| Industry for Use | Defense | |

| Quantity | Low volume | |

| Standards Met | Customer supplied specifications ANSI/ESD S20.20 | IPC J-STD-001 IPC/JEDEC J-STD-033 |

| Project Name | Hot Solder Dip of a QFN |