Robotic Hot Solder Dip

Tin mitigation – Gold Removal – Solderability Enhancement

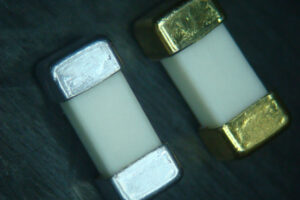

With our automation capabilities, such as robotic load/unload/transfer and auto flux/pre-heat, we can precisely tin products running the spectrum of electronic components, including devices ranging from 0603 chips, QFPS, and BGA’s. While maintaining accuracy within 0.003 inches, we can hand you proof that we performed as promised when the job is complete.

Manual Hot Solder Dip Process

Though hot solder dip tinning has always been one of the mainstays of the electronics industry, Tintronics Industries has that process-perfected down to a science. We can manually process orders using Tin-lead (Sn63-Pb37), tin-silver-copper (SAC-305), or other specialty alloys upon request.

We can easily reach high or low-volume production levels (though expedite services are available). Contact us today or keep browsing our website for further information about Tintronics and what we do.

From pre-heat to post-dip, we can easily reach production levels of high or low-volume (though expedite services are available). For further information about Tintronics and what we do, contact us today or keep browsing our website.